Current Program

Development & Deployment of The Alphabeam™ Neutron System

At TAE Life Sciences we are pushing the boundaries of science to create an innovative biologically targeted radiation therapy for cancer. We combine deep understanding of particle accelerators and recent advances in neutron generation to provide an in-hospital accelerator-based neutron source used for BNCT (Boron Neutron Capture Therapy.)

BNCT has demonstrated compelling responses for recurrent or refractory cancers, including head and neck cancers, glioblastoma, osteosarcoma, melanoma, liver caners and has been successful in treating cancer patients for whom other treatment options have been exhausted.

highlights

-

manage the design, integration and Implementation of hardware & Software components into the system.

Lead the design, integration and implementation of hardware and software components into the AlphaBeam system, guiding cross-functional teams across Mechanical, Electrical, Electronics, Ancillary, Physics, Software and Controls through each project phase, from concept to execution, while managing interdependencies, risks, and ensuring seamless system compatibility.

-

Demonstrate Adaptability and Resourcefulness In Complex Environments

Navigating shifting project requirements and integrating new priorities without compromising quality or timelines. Skilled in reprioritizing resources and aligning teams quickly to ensure project objectives are consistently met in within rapidly shifting environments.

-

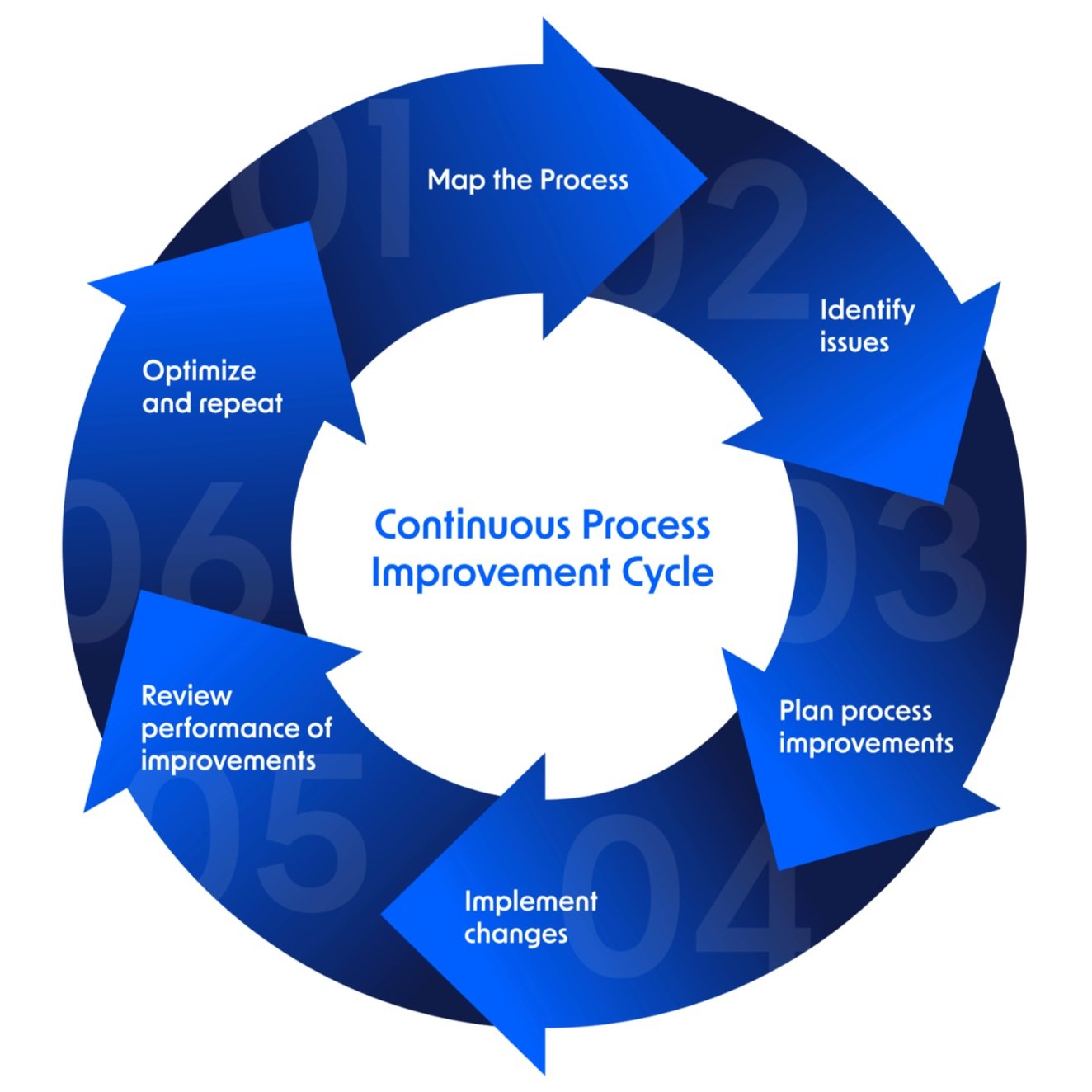

Identify and resolve gaps in Processes and Procedures Boosting Operational Efficiency

Leverage Lean project management methodologies to enhance operational efficiency across Design, Manufacturing, Quality, and Procurement departments. By leading process optimization initiatives, I foster a culture of continuous improvement and enable cross-functional teams to meet deadlines more effectively while optimizing resource usage. I’m currently working on revamping our documentation approach. Reviewing our current procedure suite and revising it to meet quality standards while being less burdensome on the SMEs, the technical writers and the manufacturing teams executing the work.